Image 1 of 1

Image 1 of 1

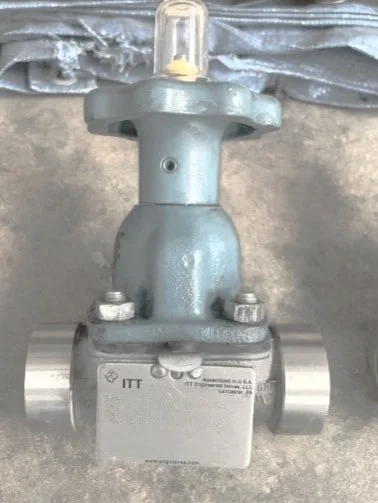

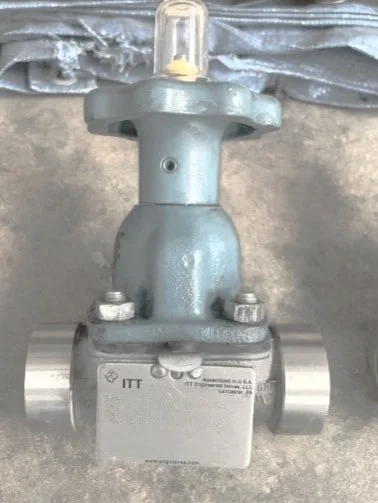

1 in Diaphragm Valve Bonnet

1 in Diaphragm Valve Bonnet

1 in Diaphragm Valve Bonnet

Description

Component: Bonnet for a 1-inch diaphragm valve.

Purpose: Provides a pressure-tight cover for the valve body, retaining the diaphragm, stem, and internal assembly while allowing actuator or manual stem operation through a sealed interface.

Material: Stainless steel 316 (standard); alternatives: carbon steel (painted), Hastelloy C-276, or duplex stainless steel for corrosive environments.

Finish: Smooth machined interior; external finish to customer specification (passivized for stainless, epoxy-coated for carbon steel).

Nominal Dimensions

Valve size: 1 in (DN25)

Bonnet outer diameter: typically sized to match valve body — commonly 2.0–3.0 in depending on valve design

Bolt circle and bolt hole pattern: per OEM valve standard (usually 4–6 bolts for 1 in size)

Height (overall): approximately 1.5–3.0 in above the valve body flange

Stem clearance and packing chamber depth: sized to accept standard packing gland or O-ring sealing arrangement for diaphragm valves

Sealing and Fastening

Sealing method: Elastomer diaphragm compression against seat; bonnet provides clamping and contains diaphragm. Stem-to-bonnet seal via O-ring or gland packing depending on actuator type and pressure rating.

Gasket material (body-bonnet joint): PTFE, graphite, or elastomeric gasket matched to service temperature and media compatibility.

Fasteners: Stainless steel studs/bolts and nuts; grade 316 or 304 for standard service, duplex or higher-alloy fasteners for corrosive applications.

Pressure & Temperature Ratings

Pressure class: Commonly rated for ASME Class 150 or PN16 for 1 in diaphragm valves; consult OEM for specific rating.

Temperature range: Dependent on diaphragm and gasket materials. Typical range with EPDM diaphragm: -20°C to +120°C (-4°F to 248°F). With PTFE diaphragm: -40°C to +200°C (-40°F to 392°F).

Compatibility & Application Notes

Suitable for liquids, slurries, and gases where diaphragm isolation is required to protect the actuator and external environment from process media.

Common industries: water treatment, chemical processing, pharmaceutical, food and beverage, and slurry handling in geotechnical construction.

When handling abrasive slurries or solids, consider reinforced diaphragms and larger bonnet clearance to avoid premature wear.

Actuation Interfaces

Manual: Handwheel or lever connection to stem via bonnet-mounted retainer.

Pneumatic / Electric actuators: Bonnet designed with standardized mounting pad and coupling to accept quarter-turn or linear actuators as specified by OEM.

Inspection & Maintenance

Routine inspection: Check bonnet fasteners for torque, inspect stem seal for leakage, and examine bonnet for corrosion or cracking.

Diaphragm replacement: Bonnet removal required for diaphragm access. Follow OEM procedure to avoid damage to diaphragm seating surfaces.

Spare parts recommendations: Keep at least one spare diaphragm and bonnet gasket per valve in critical service.

Manufacturing & Quality

Manufacturing standards: Machined to tolerances per OEM drawing; material traceability and mill certificates for pressure-retaining components.

Testing: Pressure-tested as part of valve assembly to hydrostatic or pneumatic test standard per client/OEM requirements.

Ordering Information

Provide valve model, OEM part number, valve size (1 in), material specification, pressure class, actuator type, and any special finishes or coatings when requesting replacement bonnet.

Notes

The bonnet is specific to the valve design; verify dimensional compatibility and OEM mounting patterns before procurement.

For geotechnical construction applications where contamination control is critical, specify hygienic finishes or lined bonnets as required.

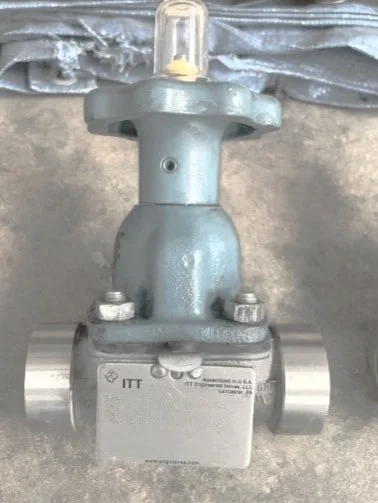

1 in Diaphragm Valve Bonnet

1 in Diaphragm Valve Bonnet

Description

Component: Bonnet for a 1-inch diaphragm valve.

Purpose: Provides a pressure-tight cover for the valve body, retaining the diaphragm, stem, and internal assembly while allowing actuator or manual stem operation through a sealed interface.

Material: Stainless steel 316 (standard); alternatives: carbon steel (painted), Hastelloy C-276, or duplex stainless steel for corrosive environments.

Finish: Smooth machined interior; external finish to customer specification (passivized for stainless, epoxy-coated for carbon steel).

Nominal Dimensions

Valve size: 1 in (DN25)

Bonnet outer diameter: typically sized to match valve body — commonly 2.0–3.0 in depending on valve design

Bolt circle and bolt hole pattern: per OEM valve standard (usually 4–6 bolts for 1 in size)

Height (overall): approximately 1.5–3.0 in above the valve body flange

Stem clearance and packing chamber depth: sized to accept standard packing gland or O-ring sealing arrangement for diaphragm valves

Sealing and Fastening

Sealing method: Elastomer diaphragm compression against seat; bonnet provides clamping and contains diaphragm. Stem-to-bonnet seal via O-ring or gland packing depending on actuator type and pressure rating.

Gasket material (body-bonnet joint): PTFE, graphite, or elastomeric gasket matched to service temperature and media compatibility.

Fasteners: Stainless steel studs/bolts and nuts; grade 316 or 304 for standard service, duplex or higher-alloy fasteners for corrosive applications.

Pressure & Temperature Ratings

Pressure class: Commonly rated for ASME Class 150 or PN16 for 1 in diaphragm valves; consult OEM for specific rating.

Temperature range: Dependent on diaphragm and gasket materials. Typical range with EPDM diaphragm: -20°C to +120°C (-4°F to 248°F). With PTFE diaphragm: -40°C to +200°C (-40°F to 392°F).

Compatibility & Application Notes

Suitable for liquids, slurries, and gases where diaphragm isolation is required to protect the actuator and external environment from process media.

Common industries: water treatment, chemical processing, pharmaceutical, food and beverage, and slurry handling in geotechnical construction.

When handling abrasive slurries or solids, consider reinforced diaphragms and larger bonnet clearance to avoid premature wear.

Actuation Interfaces

Manual: Handwheel or lever connection to stem via bonnet-mounted retainer.

Pneumatic / Electric actuators: Bonnet designed with standardized mounting pad and coupling to accept quarter-turn or linear actuators as specified by OEM.

Inspection & Maintenance

Routine inspection: Check bonnet fasteners for torque, inspect stem seal for leakage, and examine bonnet for corrosion or cracking.

Diaphragm replacement: Bonnet removal required for diaphragm access. Follow OEM procedure to avoid damage to diaphragm seating surfaces.

Spare parts recommendations: Keep at least one spare diaphragm and bonnet gasket per valve in critical service.

Manufacturing & Quality

Manufacturing standards: Machined to tolerances per OEM drawing; material traceability and mill certificates for pressure-retaining components.

Testing: Pressure-tested as part of valve assembly to hydrostatic or pneumatic test standard per client/OEM requirements.

Ordering Information

Provide valve model, OEM part number, valve size (1 in), material specification, pressure class, actuator type, and any special finishes or coatings when requesting replacement bonnet.

Notes

The bonnet is specific to the valve design; verify dimensional compatibility and OEM mounting patterns before procurement.

For geotechnical construction applications where contamination control is critical, specify hygienic finishes or lined bonnets as required.